Z.P.E. Zero Pollution Energy is the new revolutionary and patent-pending Aluminium heating system entirely developed by Presezzi Extrusion.

The Z.P.E. is a magnetic induction oven suitable for aluminum alloy or non-ferrous material billets.

Z.P.E. is the optimum system for billet heating also thanks to its low energy consumption equal to 165 kWh/t*

* the value is measured on the average of the real consumption obtained from existing magnetic heaters and it varies depending on production

The heating of the billet is obtained thanks to the magnetic field that is created during the rotation of the permanent magnets, assembled inside the rotor of a coaxial motor.

The force lines that are created by the magnetic field penetrate deeply into the material, thereby obtaining the heating effect. According to the maximum length of the billet, the solution provides the use of different sectors or zones, in order to cover the entire length of the billet.

Thanks to the independent heating sections of the Z.P.E. which are controlled by a frequency converter, simply acting on the rotation speed of each sector it is possible to obtain different temperature results in the same cycle time.

The Z.P.E. makes an accurate calculation and control of the heating process taking into account the type of alloy and the starting temperature. It automatically calculates the exact processing time and speed with real-time adjustment to obtain the desired temperature. When the billet is loaded into the furnace it is blocked between a mechanical support, which will be the reference point, and a movable stop which adapts its position according to the billet length.

When the billet is locked, the furnace moves along to cover the length of the billet and then the heating starts. The furnace moves horizontally and is actuated by a linear actuator provided with electric servomotor.

Environmental Product Declaration

ZPE has a certified Environmental Product Declaration (EPD) giving information about the environmental performance and contents, which has been controlled and verified according to the requirements of the International EPD® System.

POTENTIAL ENVIRONMENTAL IMPACT Global Warming Potential (GWP) 96 kg CO2eq*

* figure per tonne of heat-treated aluminium. In reference to ZPE 10", billet length 1500 mm

Registration number: S-P-06355 - More information is available at www.envirodec.com

MAIN ADVANTAGES

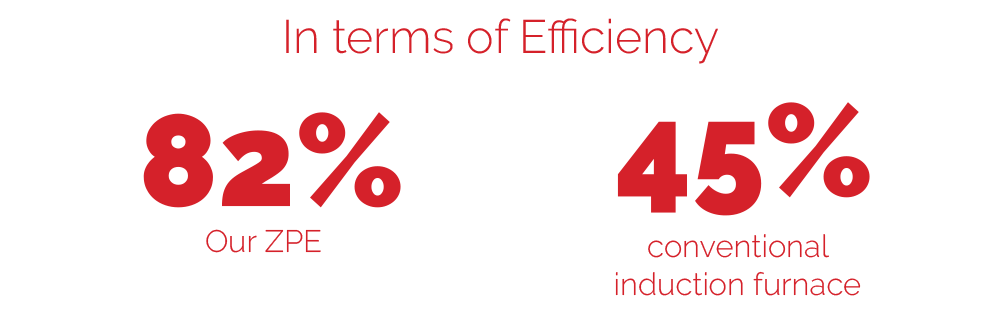

- High energy efficiency: more than 82%

(better then any other conventional system available) - Significant energy eaving

- Low environmental impact

- Specific recipes for each type of alloy

- Compact dimensions

- Contained mass

- Extremely contained installation costs

- Low maintenance costs

- System adaptable to various billet lengths and diameters

- No water consumption for cooling requiements

- No need to install cumbersome isolation transformers

- No need for foundation work

- Horizontal and Vertical versions available